Catalyst Research

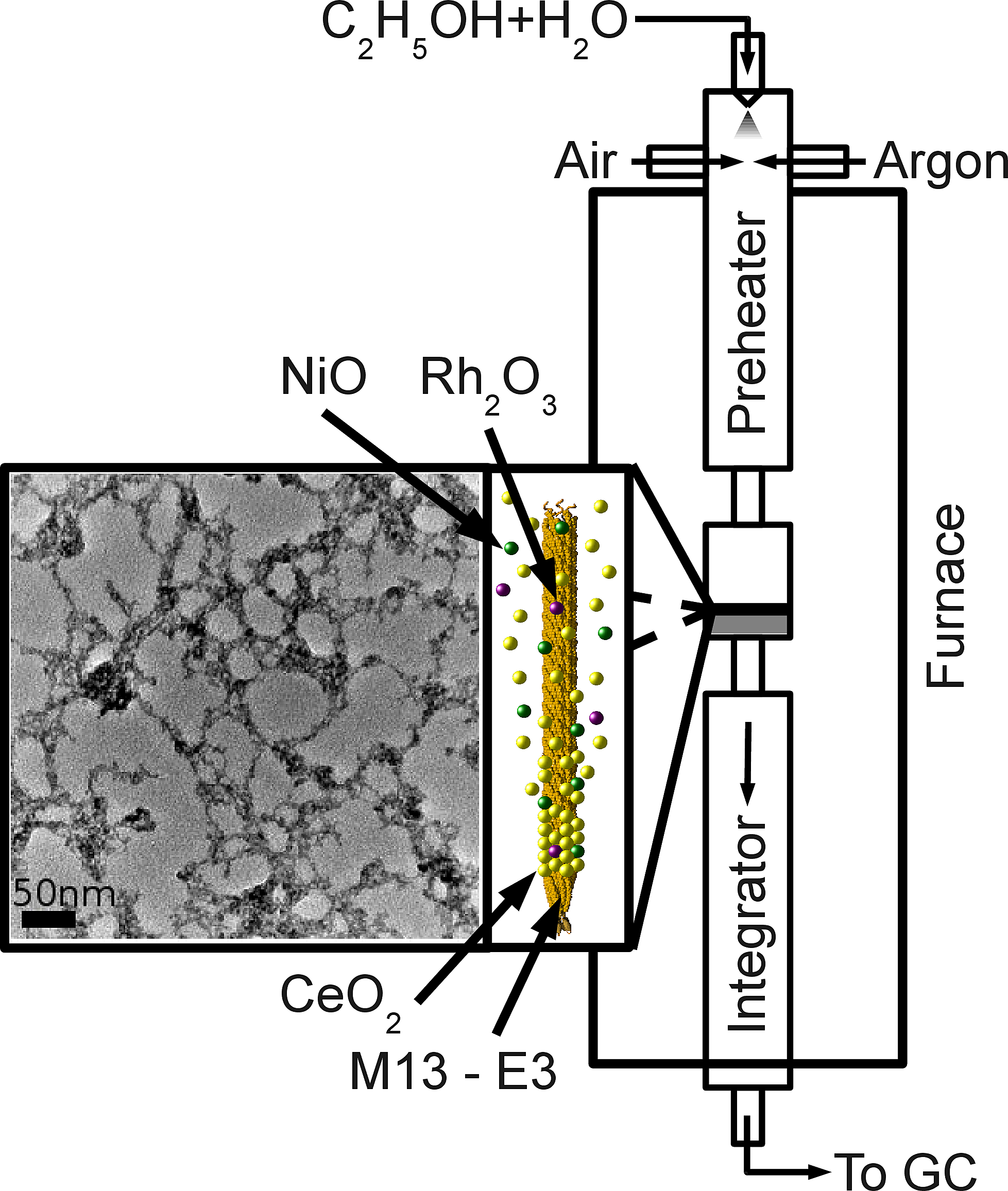

Modified M13 Bacteriophage with Ceria Coating

Brian has been working to develop novel heterogeneous catalysts for almost ten years. Heterogeneous catalysts are a particularly fascinating area which is uniquely critical in improving the human condition, but also incredibly poorly understood in a general sense.

Most recently, Brian has been applying this expertise at Visolis, where he improved the yield in producing one chemical from 20% to 97% using a reactor he designed and constructed, as well as developing analytical methods for quantifying performance. He also identified a new key target molecule and improved yields to over 60%. During this time, he led a team of three interns and one full-time employee, developed SOPs and test plans, built new analytical tools for fermentation systems to improve the ease of experimentation, and implemented design of experiment methodology to analyze results. He also managed an outside independent verification of yield results with PNNL, and assisted with writing multiple awarded Phase I and Phase II SBIR grants.

In pursuit of these goals, Brian also independently designed and implemented an electronic control system with integrated analog dimmable power controllers and thermocouples for furnace control, DC power outputs for control of valves, analog outputs and inputs for flow controller and sensor integration, and communication ports for integrating off-the-shelf digital devices such as pumps.

In the future, Brian would very much like to work on applying machine learning to close the loop around the automated testing described below using tools such as Adaptive Design in order to rapidly learn about the parameter space involved in doing chemistry and ultimately in doing catalyst discovery and full-process learning by incorporating in the costs of different reagents and processes to identify the lowest cost routes to new molecules or existing molecules using new feedstocks.

Background

Heterogeneous catalysts are just a bit too large in size to really understand them using pure physics and quantum mechanics. Typically the active areas incorporate hundreds of relevant sites, and the surface topology and attached groups dramatically impact performance. However, they are just small enough that it is conceivable to think about them using non-statistical methods, and potentially develop a robust understanding of the fundamental processes involved.

Current tools for developing catalysts are largely a shotgun approach -- starting from something that somewhat works, and then modifying it to see if there is an improvement. This approach requires massive technological sophistication to test in a robust way, and the entire field lends itself nicely to massive leaps in performance when someone thinks of something just a bit new.

Brian would like to use machine learning approaches to try to teach a computer to identify the features of a catalyst that are relevant to performance in different chemical reactions, and incorporate this with similar expert systems from biology and chemistry along with cost information and Adaptive learning schemes to close the loop around chemistry and catalyst discovery.

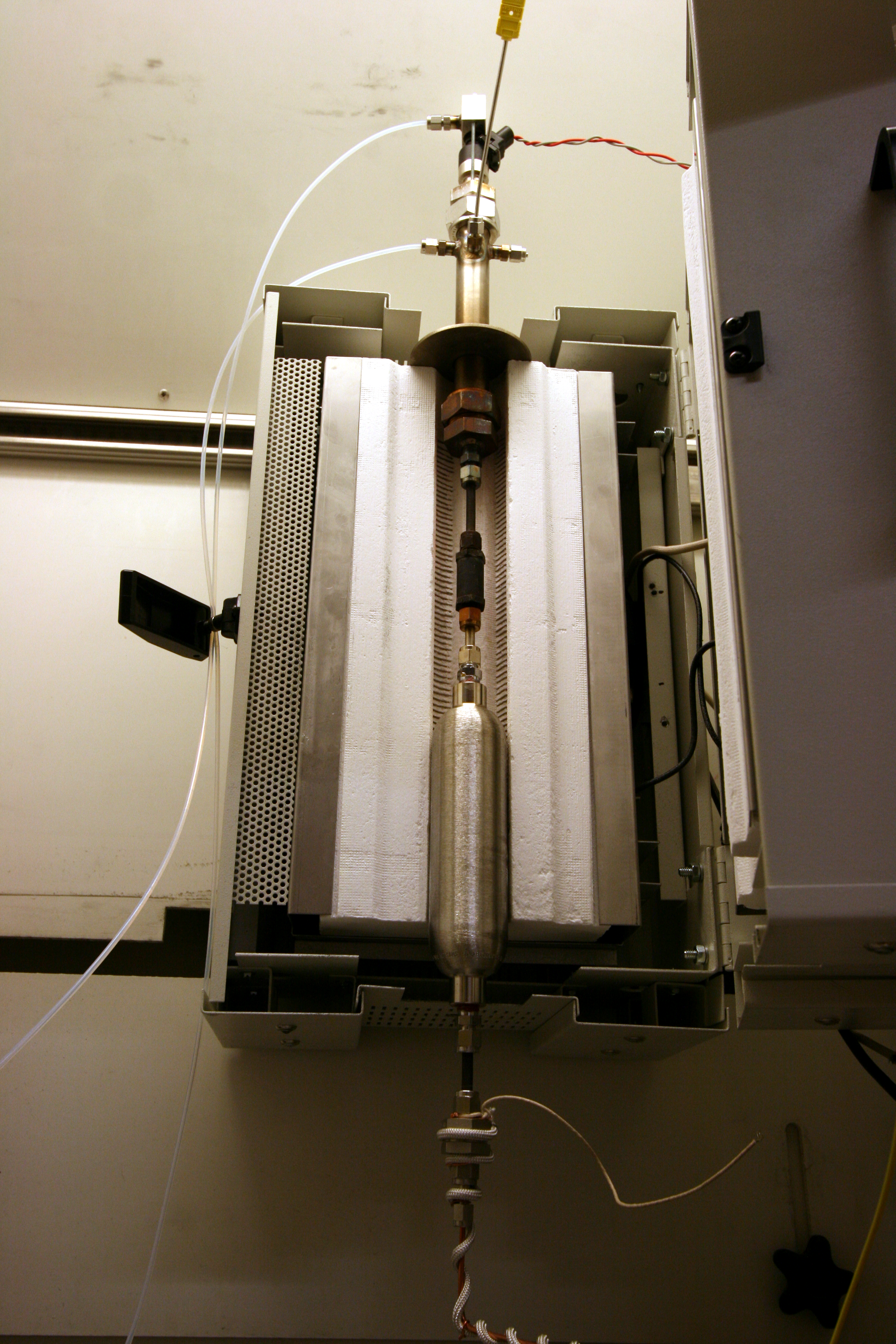

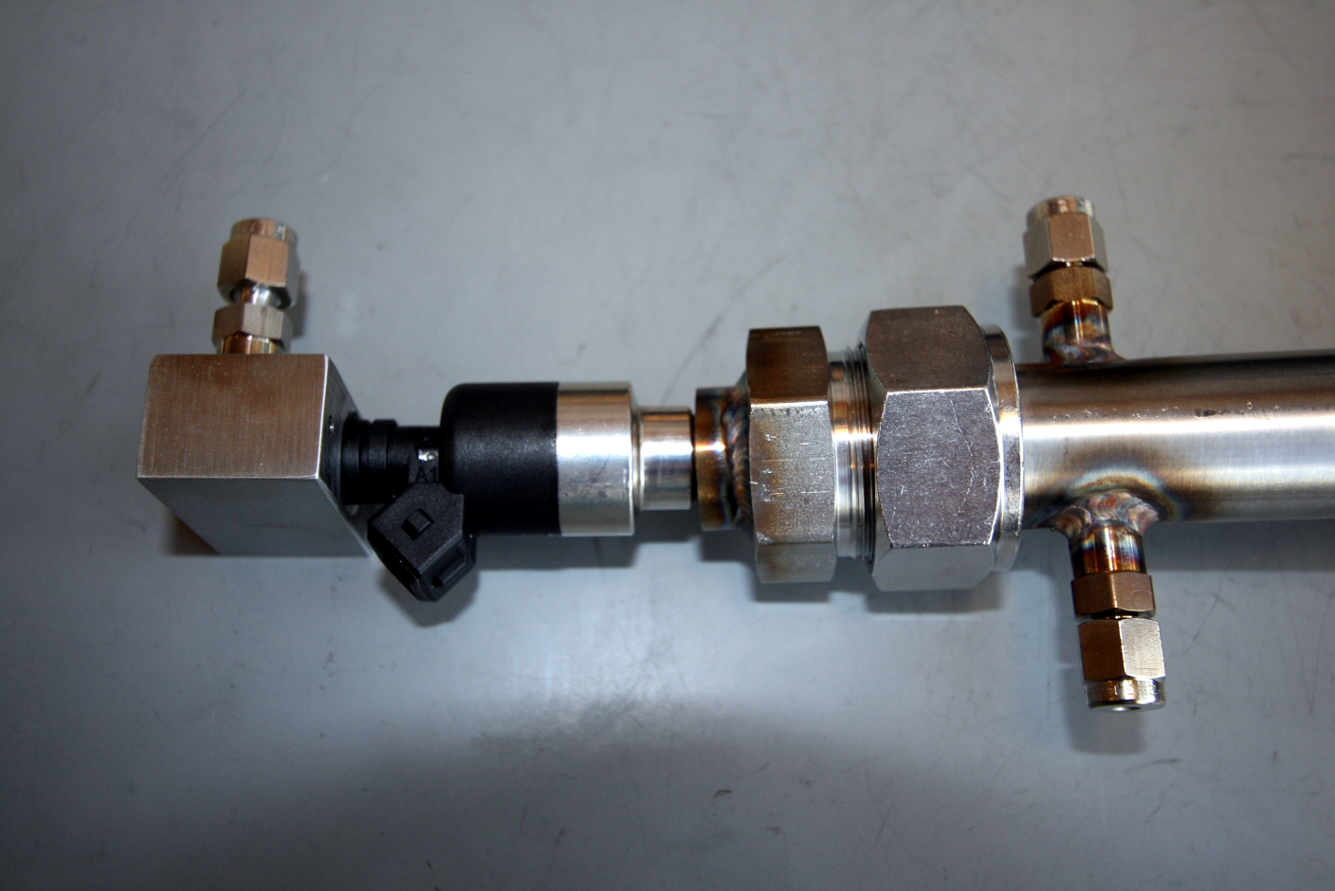

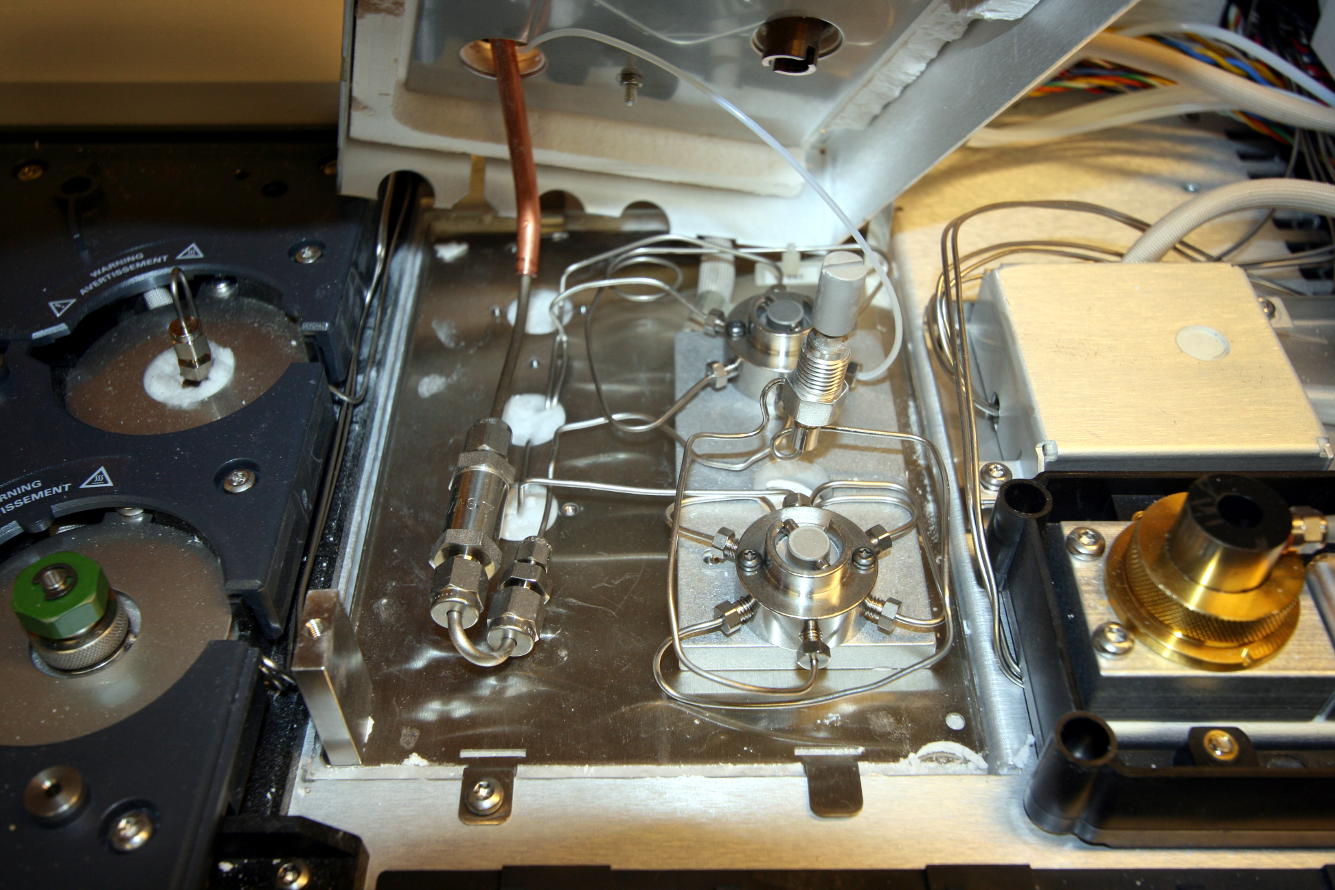

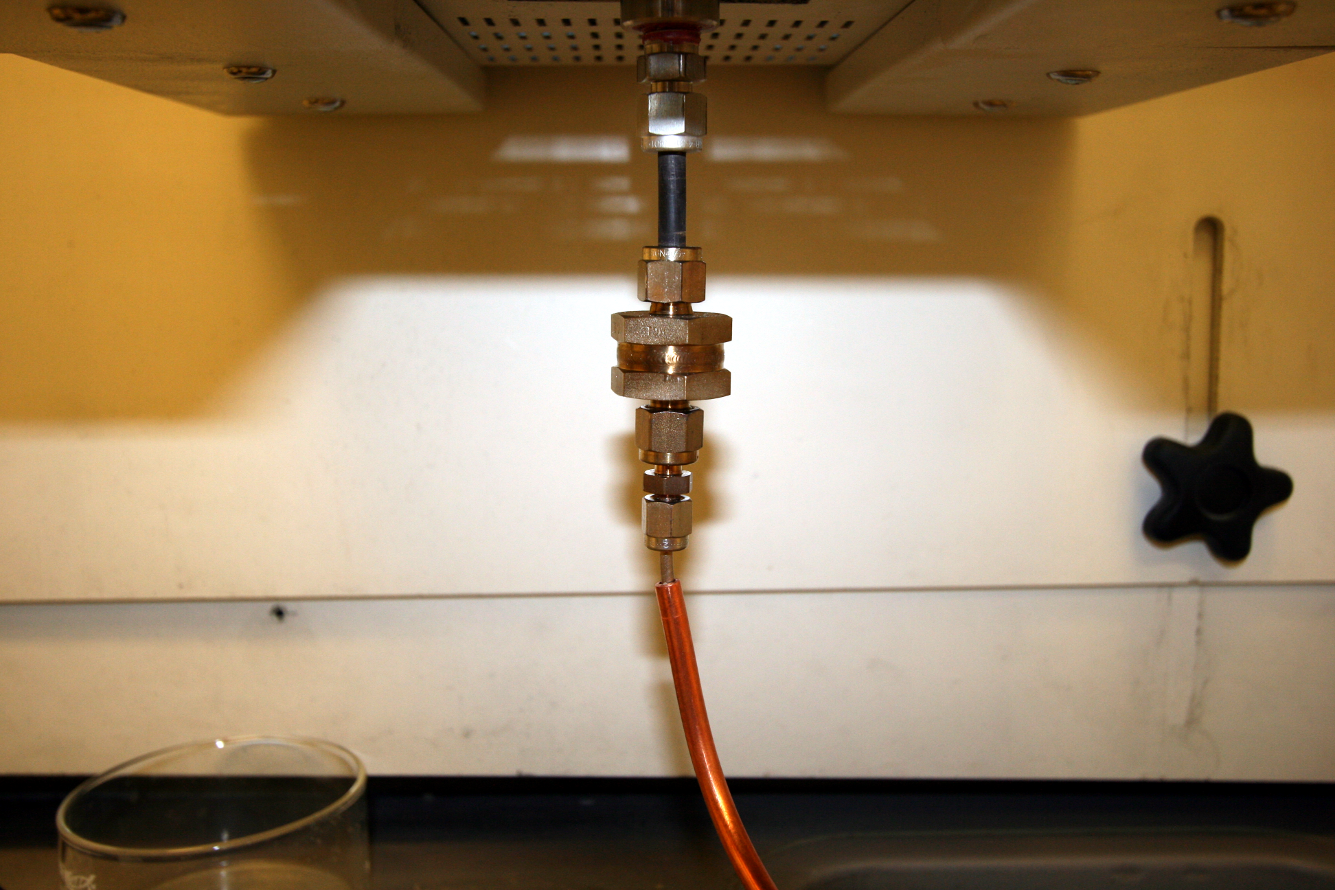

Custom Reactor for Ethanol Reforming

Brian's first project in catalysis was during his Ph.D. where he developed a way to bioengineer the M13 bacteriophage to template cerium oxide, nickel, and rhodium into a highly active structure. This technology was awarded a patent, and is now being commercialized by Siluria, a company developing tools for converting natural gas into chemical products.

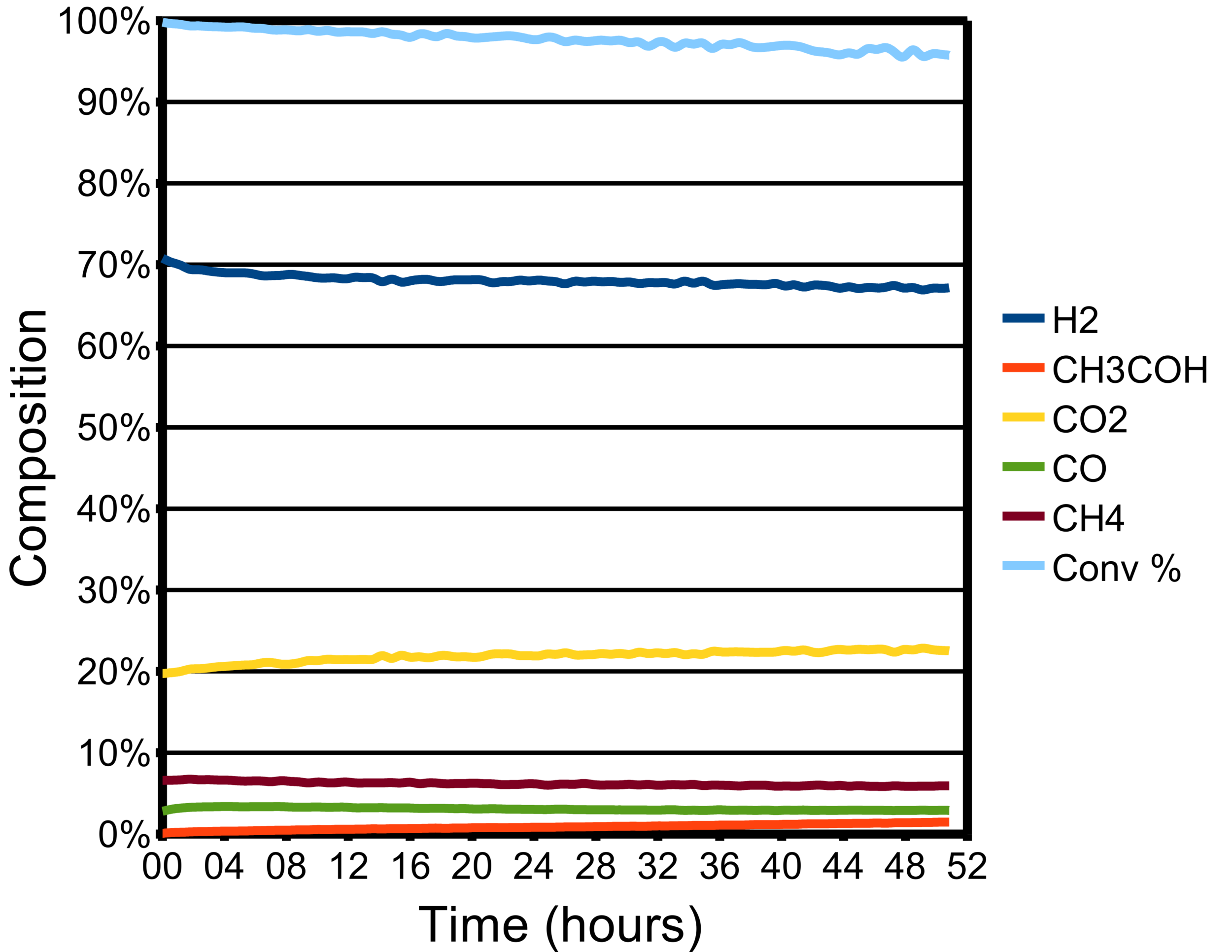

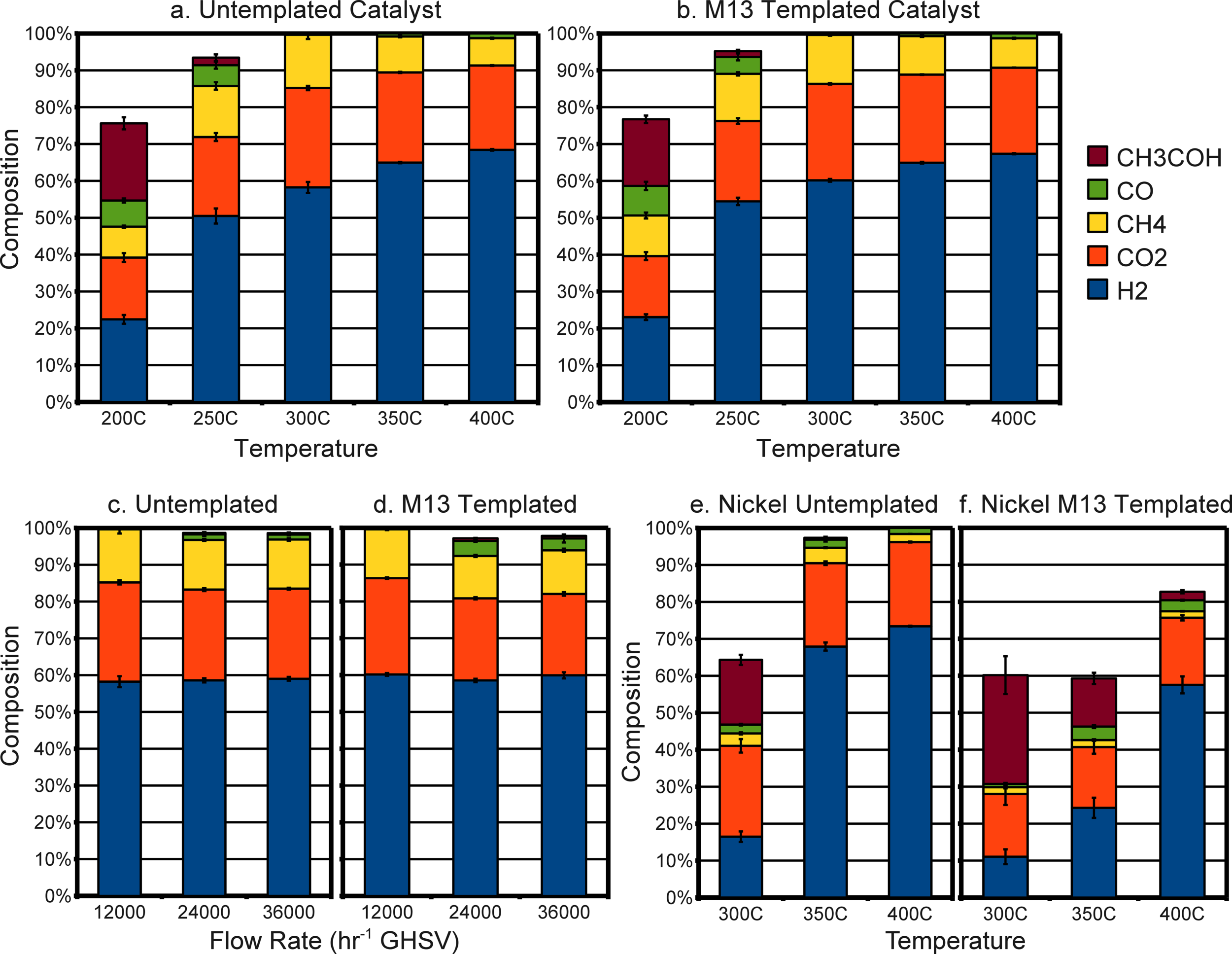

During the course of this work, Brian developed unique new tools for analyzing and understanding the thermal degradation of cerium oxide based catalysts, and managed to improve the activity of a rhodium-nickel-ceria catalyst enough in the reforming of ethanol into hydrogen gas that he was able to remove rhodium entirely from the catalyst formulation while still achieving <5% CO concentrations at just 400C.

After discovering this love of the field of catalysis, Brian moved to a postdoc where he worked with the National Renewable Energy Laboratory and The University of Colorado as a postdoctoral researcher in Professor Alan Weimer's group. This work was focused on the Upgrading of Pyrolysis oil into a bio-oil with a low enough acid content to be compatible with current refinery technology.

After this postdoc, Brian founded Navolta, which was originally going to investigate the use of ALD deposited catalysts inside of microreactor systems for chemical manufacturing. Navolta eventually moved to doing thin film coatings onto particles of copper flake for use in conductive pastes for solar panel manufacturing.